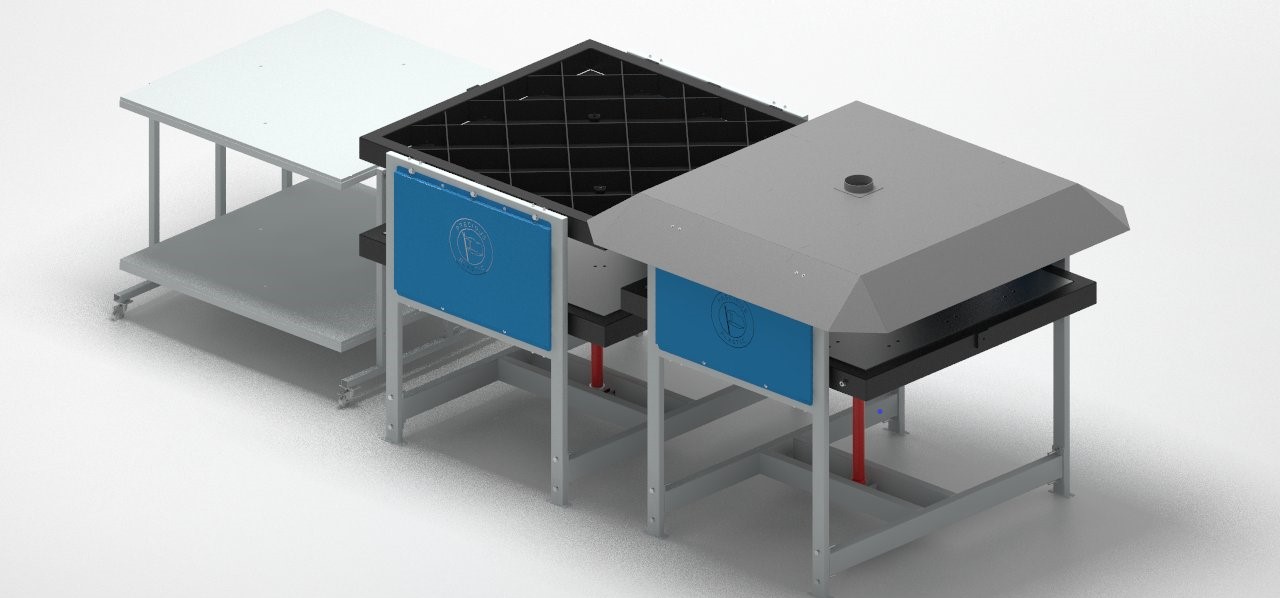

Sheet Press System

A plastic sheet press machine is a machine used for the production of plastic sheets. These machines work by heating a plastic material (such as polyethylene or polypropylene) to its melting point and then applying pressure to mold it into the desired shape. Sheet press systems feature important components like a mold, a heating element, and a hydraulic press. To use the machine, the operator first selects the desired type and amount of plastic material and places it into the heating element. The heating element melts the plastic, and the molten material is then transferred to the mold.

The molten plastic is then placed into the mold and the hydraulic press is activated to apply pressure and shape the plastic into the desired shape. Once the molten plastic gets cool down and becomes solid, the final product is extracted from the mold. In short, these machines are highly automated and can produce plastic products quickly and efficiently.

As one of the leading Sheet Press Machine manufacturers in India, we aim to deliver high-quality recycling machines that can curb the impact of plastic on nature. The Sheetpress presses the shredded plastic into recycled sheets with the help of a hydraulic press

Sheet Press System Specifications | 600mm x 600mm | 1m x 1m | 1.5m x 1.5m |

Working area | 700 x 700 x 140 mm | 1100 x 1100 x 250 mm | 1500 x 1500 x 250 mm |

Max sheet output size | 600 x 600 x 25 mm | 1000 x 1000 x 25 mm | 1400 x 1400 x 25 mm |

Aluminum plate thickness | 10 mm | 10 mm | 10 mm |

Initial Power Load | 7.5 Kw | 17 Kw | 17 Kw |

Hydraulic System | Manual | Motorized | Motorized |

Pressure | 5 Tons | 10 Tons | 10 Tons |

Power Supply | Single/Three Phase 220V | Three Phase 220V | Three Phase 220V |

Cold Press | Included in the same | Separate Unit | Separate Unit |

Temperature Controller | 2 Nos (Multispan) | 2 Nos (Multispan) | 2 Nos (Multispan) |

Machine size | 900 x 900 x 1500 mm | 1250 x 1250 x 1500 mm | 1700 x 1700 x 1500 mm |

Output Time (for 8mm sheet) | 25 min per sheet | 25 min per sheet | 25 min per sheet |

Benefits of Sheet Press System

There are several benefits to using a plastic sheet press machine in the manufacturing process:

- These machines are highly automated and can produce plastic products quickly and efficiently, which can help increase productivity and reduce labor costs.

- Plastic sheet press machines can produce a wide range of plastic products in various shapes and sizes. The mold can be customized to produce products in any desired shape.

- Plastic sheet press machines can produce products with consistent dimensions and quality, ensuring that each product meets the required specifications.

- Plastic sheet press machines are much more affordable than other manufacturing procedures. The cost of the raw material is typically lower than other materials such as metal, and the cost of energy needed to operate the machine is also relatively low.

- Plastic sheet press machines can use recycled plastic materials, which helps to reduce waste and decrease the environmental impact of the manufacturing process.